A Specialized Session on Structural Engineering, Transportation and Highway Engineering, and Water Resources Engineering Was Held at the 5th International Conference on Architectural and Civil Engineering Sciences

On Wednesday, February 26, 2025, Cihan University – Erbil hosted a specialized session on Structural Engineering, Transportation and Highway Engineering, and Water Resources Engineering as part of its commitment to advancing engineering research.

The session, which took place in the VIP Hall, was chaired by Prof. Dr. Haitham Ali B. Al-Thairy from Al-Qadisiyah University, Iraq, and Dr. Diyar Nasih Qadir from Kirkuk University, Iraq, as co-chair. The event featured a keynote speech and research presentations on sustainable construction, infrastructure resilience, and advanced engineering materials.

The keynote speech, titled Introducing Warm Mix Asphalt Concrete (WMAC) as a Green Pavement, was presented by Prof. Dr. Saad Issa Sarsam from the University of Baghdad & Sarsam and Associates Consult Bureau (SACB). It focused on the Warm Mix Asphalt Concrete (WMAC) as a greener alternative to Hot Mix Asphalt (HMA). The findings of this study showed that WMAC had significantly higher Indirect Tensile Strength (ITS) at 25°C and 5°C compared to HMA with improvements exhibited up to 30.59%, depending on the binder type. Additionally, WMAC exhibited lower temperature susceptibility, making it more stable under varying conditions.

In the first research presentation titled Rainfall Intensity-Duration-Frequency Mapping in Iraq: A Tool for Sustainable Development Planning by the authors Dr. Asmaa Abdul Jabbar Jamel and Dr. Zainab Thair Dawood from Tikrit University, the study highlighted Iraq’s rainfall distribution with higher precipitation in the north, whereas lower precipitation in the central and southern regions. Rainfall follows topography which benefits agriculture in the north, while the south requires targeted water management. Contour mapping aids environmental planning and policy-making.

The second research was Predicting the Behavior of LWRC Beams Strengthened by NSM GFRP Rods Using the DIC Method by the authors Prof. Dr. Haitham A.B. Al-Thairy and Anees Jassim Youssef from Al-Qadisiyah University. This study evaluated NSM GFRP rods for strengthening LWRC beams, exhibiting a 30% increase in flexural load capacity and a 149% improvement in shear strength. The DIC technique accurately predicted displacement and failure modes, confirming its reliability in structural analysis.

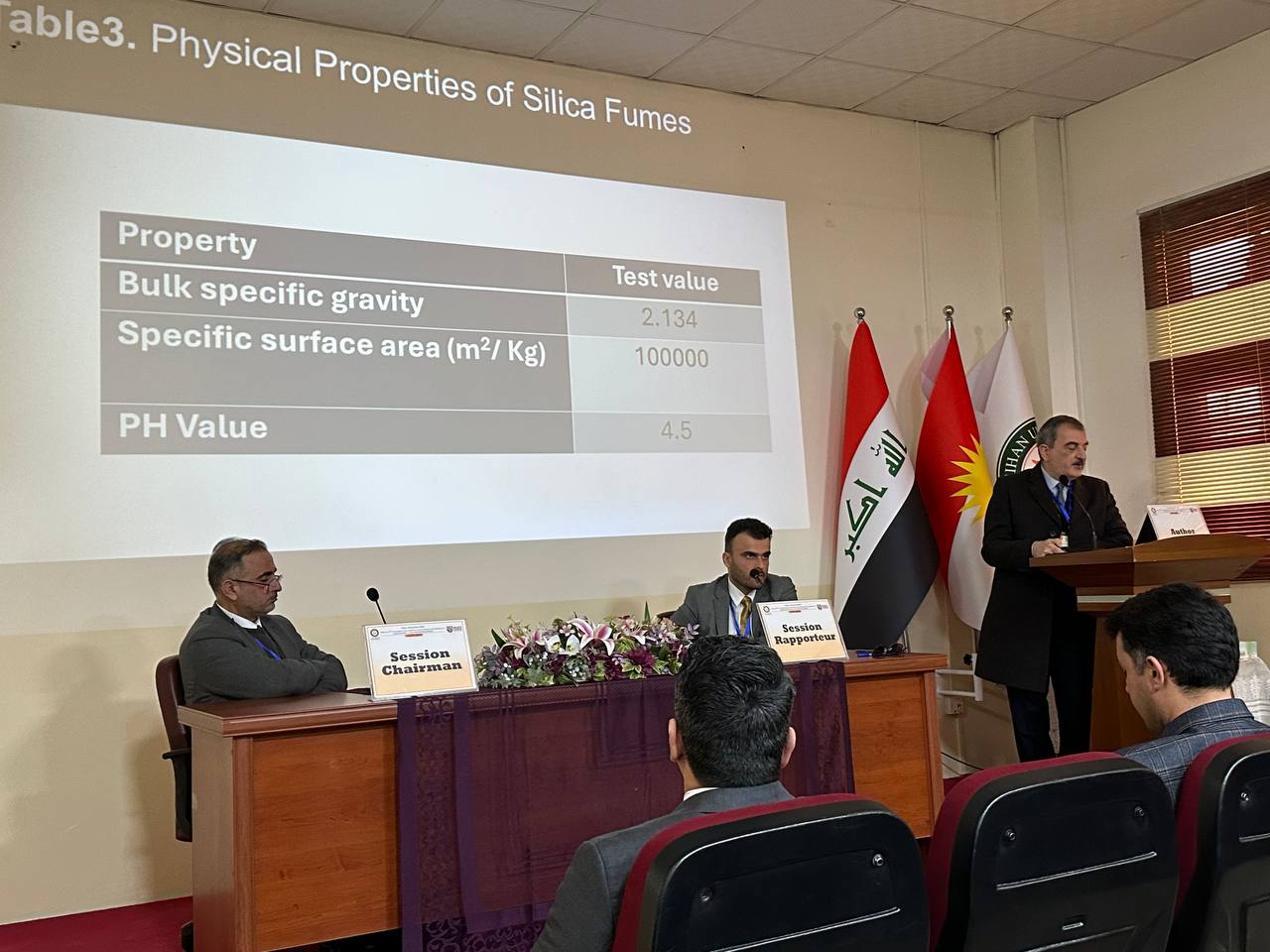

A study, titled Influence of Additives on the Rheological Behavior of Sustainable Asphalt Binder by Prof. Saad Issa Sarsam from the University of Baghdad, examined how nano- and micro-sized additives affect asphalt binders. It highlighted that nano-sized additives improved asphalt binder sustainability by reducing temperature susceptibility. Both micro and nano additives enhanced viscosity with variations, depending on the binder type. Fly ash, fumed silica, silica fumes, and hydrated lime significantly increased viscosity, supporting their effectiveness in road construction.

The next study, titled Structural Performance and Mechanical Characteristics of Concrete Incorporating Waste Glass Powder as a Partial Cement Replacement, was presented by Dr. Diyar Nasih Qadir, Dr. Khamees N. Abdulhaleem, and Hammad D. Merie from Kirkuk University. This research investigated Waste Glass Powder (WGP) as a partial cement replacement in concrete production. Key findings: Optimal replacement level: 15% WGP improved compressive strength by 14.72% and tensile strength by 22.73%. Performance variability: Using Waste Glass Powder (WGP) in concrete offers sustainability benefits without compromising strength. A 10% replacement improved tensile strength but reduced compressive strength, while 30% maintained compressive strength with a slight tensile strength reduction. WGP reduces cement use and CO₂ emissions, promoting sustainable construction and waste recycling.

Authors Gonol Ali Mardan and Dr. Mazin Burhan Abdulrahman from Tikrit University presented a paper on the Mechanical Properties of Geopolymer Concrete Reinforced with Steel Fibers Under Ambient and Elevated Temperatures. This study analyzed the mechanical performance of Geopolymer Concrete (GPC) reinforced with steel fibers, particularly under high temperatures. Key findings: Optimal fiber content: 1.0% steel fiber achieved the highest performance, Steel fibers significantly enhanced the compressive and tensile strength of geopolymer concrete, with peak performance at 1.0% fiber concentration (51.2 MPa compressive strength, 5.51 MPa tensile strength). The concrete retained its compressive strength up to 250°C, however, experienced gradual strength reduction between 250°C and 750°C. Steel fibers improved fire resistance across various temperatures.

The session highlighted innovative advancements in engineering sustainability, infrastructure resilience, and cutting-edge materials. Additionally, engaging discussions explored eco-friendly construction techniques, optimized water resource management, and pioneering reinforcement strategies, fostering meaningful academic collaboration and driving future innovation in the field.

It concluded with interactive expert discussions, where authors and attendees exchanged forward-thinking insights and sparked new ideas and collaborative opportunities for sustainable engineering solutions.