Recycle and Reuse of Glass Cans for Soft Drinks as an Alternative to Cement for Concrete Manufacturing

As a step toward a cleaner environment and to revive the concept of recycling, a group of civil engineering students at Cihan University-Erbil are starting a project to recycle and reuse glass cans for soft drinks as an alternative to cement for concrete manufacturing.

The importance of recycling is highlighted for many reasons, the most important of which are saving trees, reducing waste dumping areas, preserving natural resources and protecting them from excessive consumption. The recycling process includes many different materials such as iron and steel, glass, aluminum cans, wood, paper and other materials, the accumulation of which poses a threat to the environment. Accordingly, the glass recycling and reuse project was proposed as an alternative cement material in the manufacture of concrete and replacing the concealed ratios (20.40,60 percent of the weight of cement). The process included the following steps:

- Collect, wash and sterilize glass and remove the paper labels for each can.

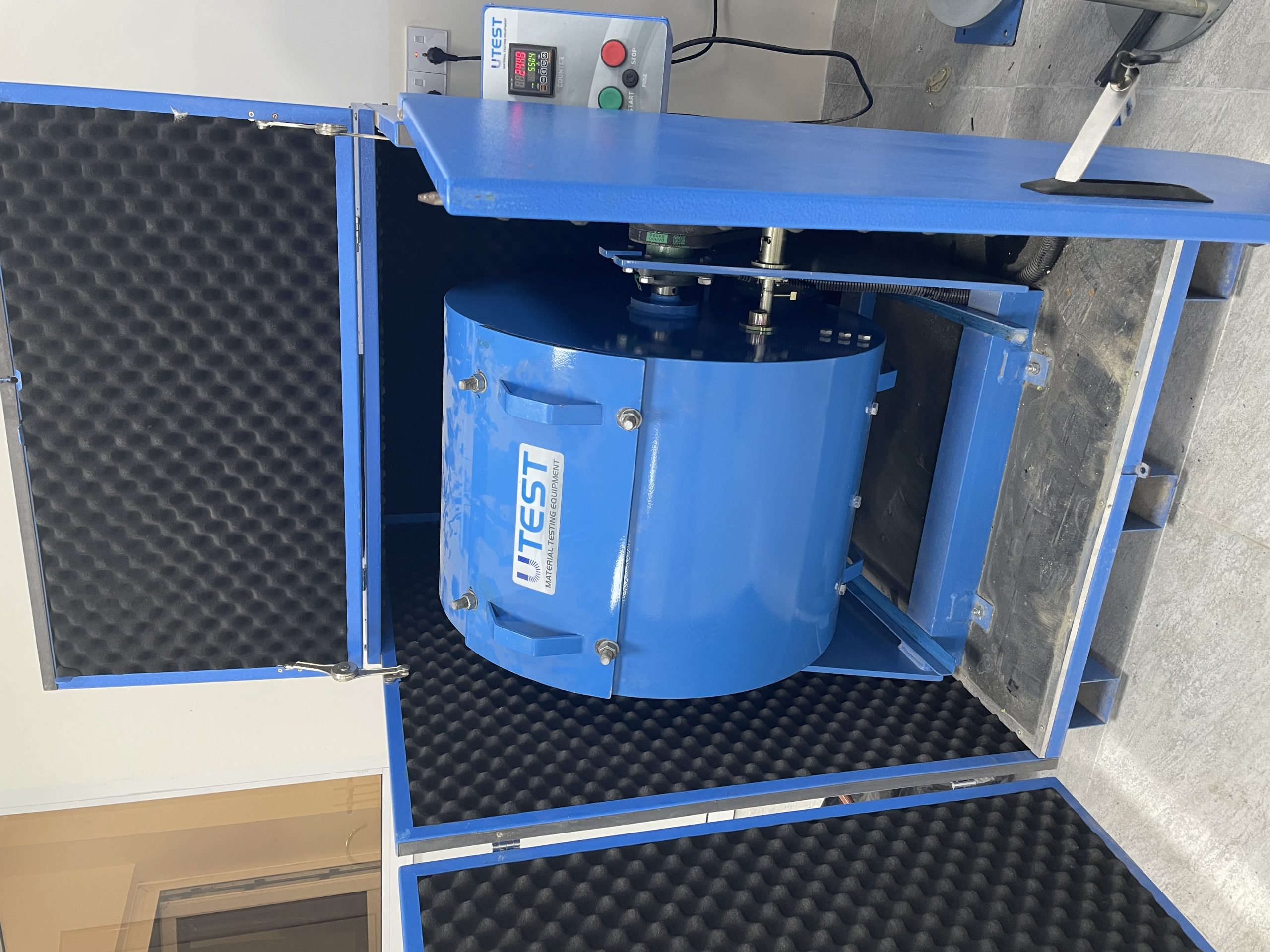

- Breaking and grinding glass using the grinding device available at Cihan University laboratories shown in the pictures.

- Production of cubic concrete samples of 10*10 cm dimensions where 3 cubes were assigned for each replacement ratio for the purpose of testing the mechanical properties of the concrete containing glass and comparing it with normal concrete after a curing period of 28 days according to the specifications.

In addition to the environmental recycling benefits, recycling has cost benefits, as the replacement of waste and harmful substances reduces the cost of producing concrete materials by a high percentage and reduces cement consumption. Students in the second stage in the Department of Civil Engineering seek to achieve positive results by recycling glass at the quality level by improving the characteristics of the concrete as well as at the level of reducing the cost of production.